Choosing a chiller refurbishment company is cost effective because the main cost of a large chiller is mostly in the fixed plant. That is to say: the two main heat exchangers and the compressor. Therefore, this is the most environmentally friendly option as the carbon footprint of building new plant is very high. This is not mentioned when you purchase a new chiller. With chiller controls replacement, this kind of plant can last for 50 years. One of our competitors has been carrying this out to a chiller that dates back to the 1970s and is still in service!

Chiller Evaporator Refurbishment Company

Refurbishment of broken tubes can be performed to beyond manufacturer's recommendations. Larger scale replacement of the tubes can be carried out giving the same lifespan of the original tubes. This is a major overhaul at a fraction of the cost of replacing the chiller.

0161 237 3727

service@maximuschillers.com

Chiller Compressor

We strip the chiller compressor down in our workshop. It is made from heavy castings so will last a very long time. We provide a 12 month warranty on all our chiller compressors. Read More about centrifugal compressor remanufacturing on our web page.

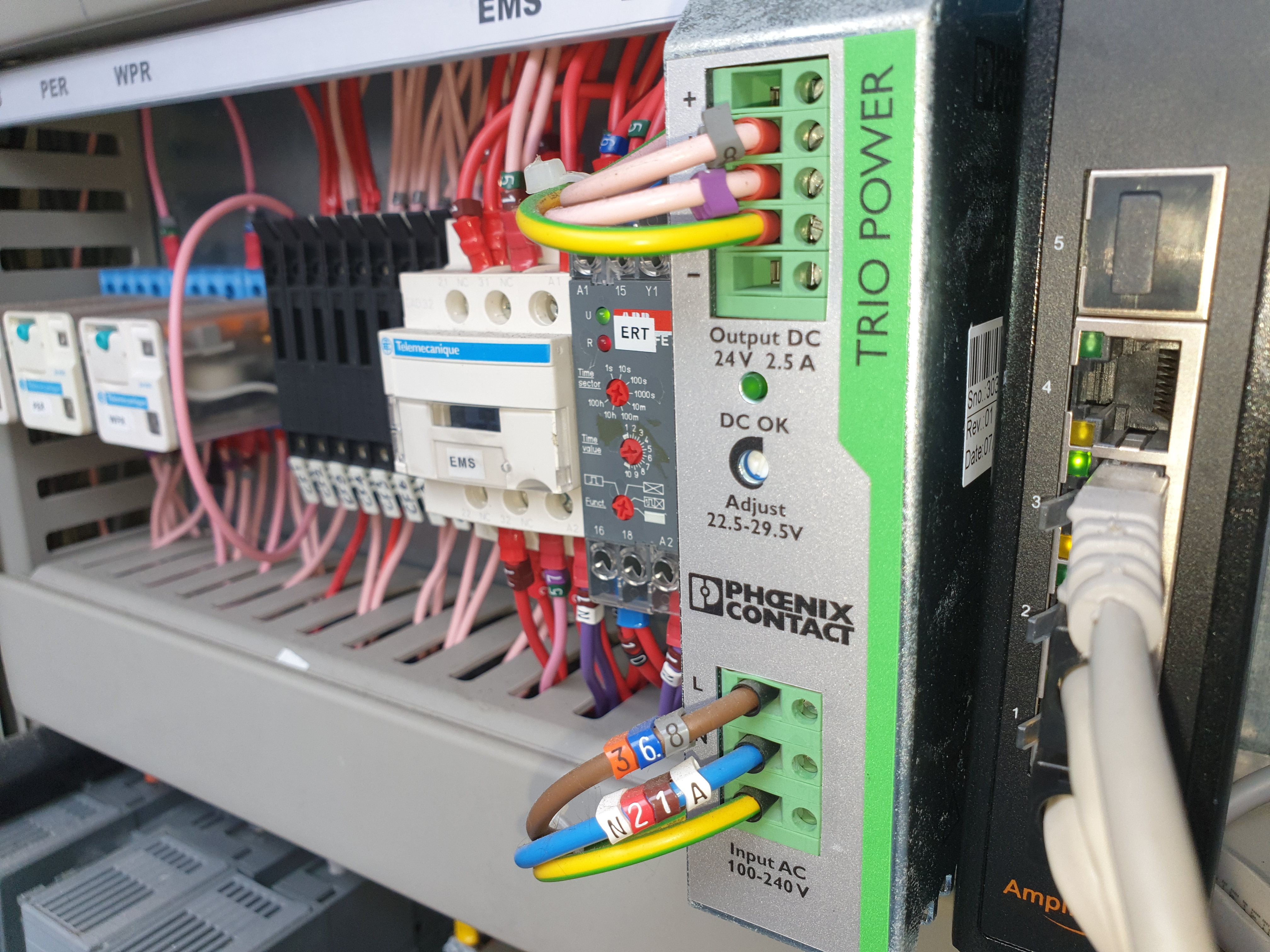

Chiller Controls

State of the art controls can be fitted. The controls that come with the chiller are often made 'in house' so they can be prone to spurious trip outs. These trip outs can cause a loss in production. A control panel designed specifically for that chiller comes ready built. All you have to do, is wire in the various sensors and transducers. The run signal, compressor soft start, remote loading and monitoring can be easily integrated. Simple and easy solutions to big problems are what we do!

Any Chiller- Any Problem- Any Part- Any Refrigerant- Anywhere- The MAXIMUS ADVANTAGE™

Related Articles:

Chiller Refurbishment Supplier

R407c Chiller Condenser Retrofitting

Chiller controls that we fit to existing chillers.