Maximus chillers provides water chiller maintenance to all kinds of machines. Some of which have kilowatt hour meters fitted. This means we can monitor the reduction in energy consumption, directly as a result of our maintenance being carried out.

Efficient Water Chiller Maintenance

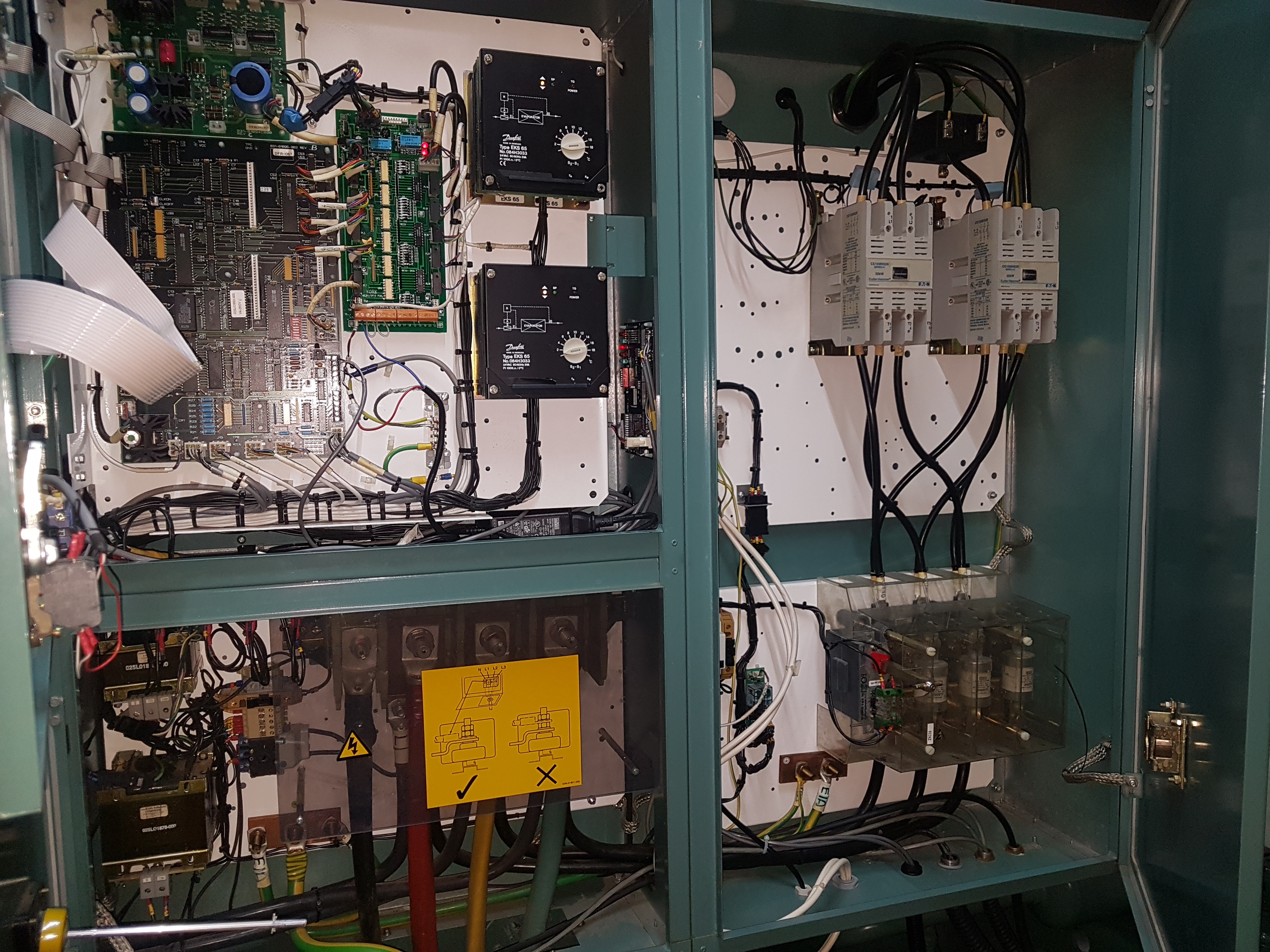

Maintenance is carried out to ensure every aspect of your chiller is running efficiently. We believe our maintenance checklist is the best in the industry. It looks in detail at the running conditions of the plant, component adjustments and the parameters in the controls. The checklist is used to assess if there are problems that are starting to occur before a safety shutdown happens. Below are some of the issues that we keep on top of to increase the efficiency of your plant.

Shell and Tube Insulation

The build up of dirt acts as an insulator in shell and tube heat exchangers. These are used for the evaporation and the condensing of the refrigerant.

The Evaporator

In the evaporator, should the tubes be fouled, there will be a reduction in latent heat absorbed into the system. This will cause the plant to stay on longer and use considerably more energy. Should the tubes become considerably fouled, the chiller will malfunction and eventually system shutdown will occur.

The Condenser

In a shell and tube condenser, the reverse of the above will occur. Tube fouling, acting as an insulator, will prohibit the rejection of heat from the system. The head pressure control will open the condenser controls to try and assist in heat rejection. Heavy fouling will cause an increase in the consumption of energy. Eventually a safety shutdown will occur causing loss of production.

0161 237 3727

service@maximuschillers.com

Compressor Loading during Water Chiller Maintenance

If the loading of the reciprocating compressors is faulty, the plant will not be able to effectively match the load.

Over Loading

Too much loading may occur, causing the water chillers to achieve set point too quickly. The plant will then go through the off cycle. This means that the plant will have to load back up, using more energy than matching the load continuously.

Under Loading

Should the plant be unable to load up to the required level to match the load, this will cause the water temperature to creep up and the lag chillers being called for to match the load. More chillers running than necessary dramatically increases energy consumption.

Related Articles:

R134a Chilling Plant Maintenance

Air Cooled Chiller Planned Maintenance

Process Chiller Maintenance Visit

Chilled Water System Maintenance

Centrifugal Chiller Maintenance

Industrial Chiller Maintenance

Planned Preventative Chiller Maintenance

Air Cooled Chiller Maintenance

Preventative Chiller Maintenance

Read about leak checking at the Refcom site